Revolutionary Particulate Matter Testing Solutions for Pharmaceutical Laboratories

Welcome to Bionter, a premium provider of cutting-edge particulate matter testing solutions. Our revolutionary technology, EVE, is designed to transform the way you detect and analyze particulate contamination in parenteral drug applications and ophthalmic solutions. With Bionter, you can achieve unparalleled accuracy and efficiency in your particle testing laboratory.

Efficient

Let your samples run overnight and maximize productivity. Bionter's EVE system offers a fully automated and smart workflow, enabling high-throughput testing while you focus on other critical tasks. Say goodbye to time-consuming manual processes and embrace streamlined efficiency.

Non-Destructive

Discover more without sacrificing your samples. Bionter's advanced solution ensures non-destructive testing, allowing you to gather comprehensive insights without compromising the integrity of your valuable samples. Get the most accurate results while preserving your resources.

Compliant

Trust in Bionter's technology that meets the highest industry standards. Our solutions are compliant with regulatory guidelines, including USP <788>, USP <787>, USP <789>, EP 2.9.19, and JP 6.07. Rest assured that your particle testing processes adhere to the strictest quality requirements.

GMP Environment Ready

Operating under a GMP environment? Bionter has you covered. Our software is fully 21CFR Part 11 compliant, ensuring data integrity, security, and traceability. Maintain compliance effortlessly and enhance your peace of mind.

Ready to elevate your particulate matter testing? Request a demo of Bionter's EVE system today and experience the future of particle analysis. Our team of experts is eager to showcase how our solutions can revolutionize your laboratory processes.

Knowledge about Particle Analysis

Understanding Particle Analysis in Biopharmaceutical Development

Sub-visible particles play a crucial role in the quality and safety of all bio-pharmaceutical products meant for infusion or injection. These particles can impact product stability, effectiveness, and overall safety. As proteinaceous particles are found in therapeutic protein products to varying degrees, effective particle monitoring becomes an essential control strategy in biotherapeutic development.

Explore the fascinating world of particle analysis, where scientists employ advanced technologies to determine the number and size of these particles. Gain insights into the methods used, their limitations, and the significance of particle analysis in ensuring the quality and safety of biotherapeutic products.

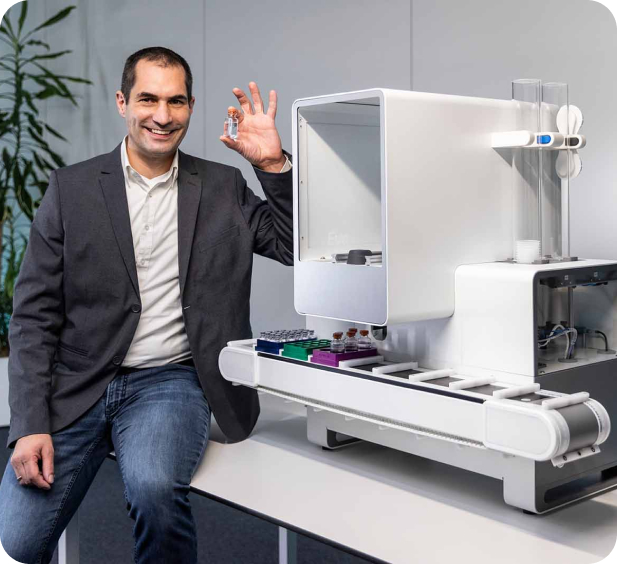

About Bionter

At Bionter, we are driven by the core idea of revolutionizing analytical testing to benefit people’s health. Our mission is founded by Tobias Werk and centered around the fundamental goal of human well-being. As an innovative start-up, we are dedicated to becoming a world-class provider of particle counters specifically tailored to the pharmaceutical and biotechnology industries. Join us as we take you behind the scenes of Bionter, introduce you to our passionate team, and share our ambitious vision.